The level measurement of a container whether liquid, solid or powder in a tank, silo, hopper is achieved by the addition of load cell.

This technique makes it possible to obtain a high accuracy if you follow the rules which you find in this article.

Choosing load cells

Different technologies of load cells exist depending on the constraints of use: bending sensor, single or double shear, compression, tension.

Determination of load cells

- Compression, tension, shearing.

Number of load cells and support points.

Weighing range and load cell capacity.

Accuracy. - Operating and functional mode:

Easy assembly and maintenance.

Transmission of the signal.

Calibration - Environmental conditions:

Climate, Wind.

Temperature.

Influence of rigid bonds

Vibration - Risk control:

Seismic risk.

ATEX explosion risk.

Number of load cells and support points

The best accuracy (< 0.5%) is obtained when the number of load cells is equal to the number of support points. In the case of a symmetrical tank containing liquid or very fluid product, it is only possible to partially equip the support points with load cells.

For example: 4 support points 2 load cells, the accuracy then could not be better than 2% depending on the case.

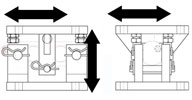

Bracket and mounting kit

Each load cell is equipped with a bracket that facilitates assembly and ensures the mechanical safety of the silo and load cell. The 300 and 400 series has jack screws for the safety of the set during installation or maintenance operations. Our brackets are calculated and tested to resist parasitic forces in the 3 planes (refer to the technical sheet of bracket).

Accuracy

Weighing accuracy is the measurement error for a load, do confuse with the display rung (multiple of 1, 2, 5). Accuracy depends on several factors:

- Load cell errors < (0.01%).

- Calibration error (automatic calibration of the indicator 0.1% or with standard masses < 0.01% ).

- Mechanical error (mechanical constraint of the ducts, bridge, cone supports …) of up to 1 t in practice.

- Combined load cell Error: E-N x Load cell.

Display and signal transmission

The LOCAL display allows signal processing and conditioning as close as possible to the source. In addition, the display is very practical for maintenance and diagnosis.

– Generally it is equipped with an analog output (4-20mA) or digital (ETHERNET, PROFINET, PROFIBUS, MODBUS…).

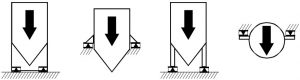

Bending sensor

Bending or simple shearing

Weighing range 10 to 5,000 kg

Series 300

Easy implementation

Integrated security

Accuracy < (0.05%)

– Limited in maximum capacity

Double shear sensor

Weighing range 5 to 100 t

Series 400

Easy implementation: effort is distributed and centered

Integrated security

Mechanical reliability (double supports)

– Accuracy ( < 0.1% )

Compression sensor

Weighing range 15 to 500 t

Series 700

Used for heavy loads > (100 t)

Load descents on selfcentering column, simplifying the design of the supports

– Very sensitive to misalignment of support

– No built-in sensor security.

Tension sensor

Weighing range 0.1 to 5 t

Series 600

Self-centering forces

Good accuracy (0.1%) – Complicated implementation – No built-in sensor security, provide security in case of a rupture

Documents pdf

- TELEMETRIX_46903XL-a.pdf (177.63 Kb)

- TELEMETRIX_610_fr-es.pdf (222.67 Kb)

- TELEMETRIX_AXE_PESEUR_LOAD_PIN.pdf (135.66 Kb)

- TELEMETRIX_CAPTEUR_190_es_en.pdf (663.4 Kb)

- TELEMETRIX_CAPTEUR_300_es_en.pdf (869.52 Kb)

- TELEMETRIX_CAPTEUR_350_es_en.pdf (1.3 Mb)

- TELEMETRIX_CAPTEUR_420_es_en.pdf (189.54 Kb)

- TELEMETRIX_CAPTEUR_650_es_en.pdf (301.04 Kb)

- TELEMETRIX_CAPTEUR_PESAGE_CROCHET_540.pdf (163.54 Kb)

- TELEMETRIX_LOAD_CELL_740_fp_es_en.pdf (1.01 Mb)

- TELEMETRIX_Manuel Accessoire 46901-46902-46903_En.pdf (809.19 Kb)

- TELEMETRIX_Manuel_Montage_46901-46902-46903_Fr.pdf (1.03 Mb)

- TELEMETRIX_NOTICE_MONTAGE_35902-35903_eng.pdf (709.58 Kb)

- TELEMETRIX_PESAGE_SILO_En.pdf (864.76 Kb)

- TELEMETRIX_PESAGE_SILO_fr.pdf (3.99 Mb)

- TELEMETRIX_capteur_200_es_en.pdf (299.87 Kb)

- TELEMETRIX_capteur_230_es_en.pdf (238.39 Kb)

- TELEMETRIX_capteur_340_es_en.pdf (435.9 Kb)

- Telemetrix_capteur_460.pdf (259.11 Kb)

0 Comments